Chemical Milling

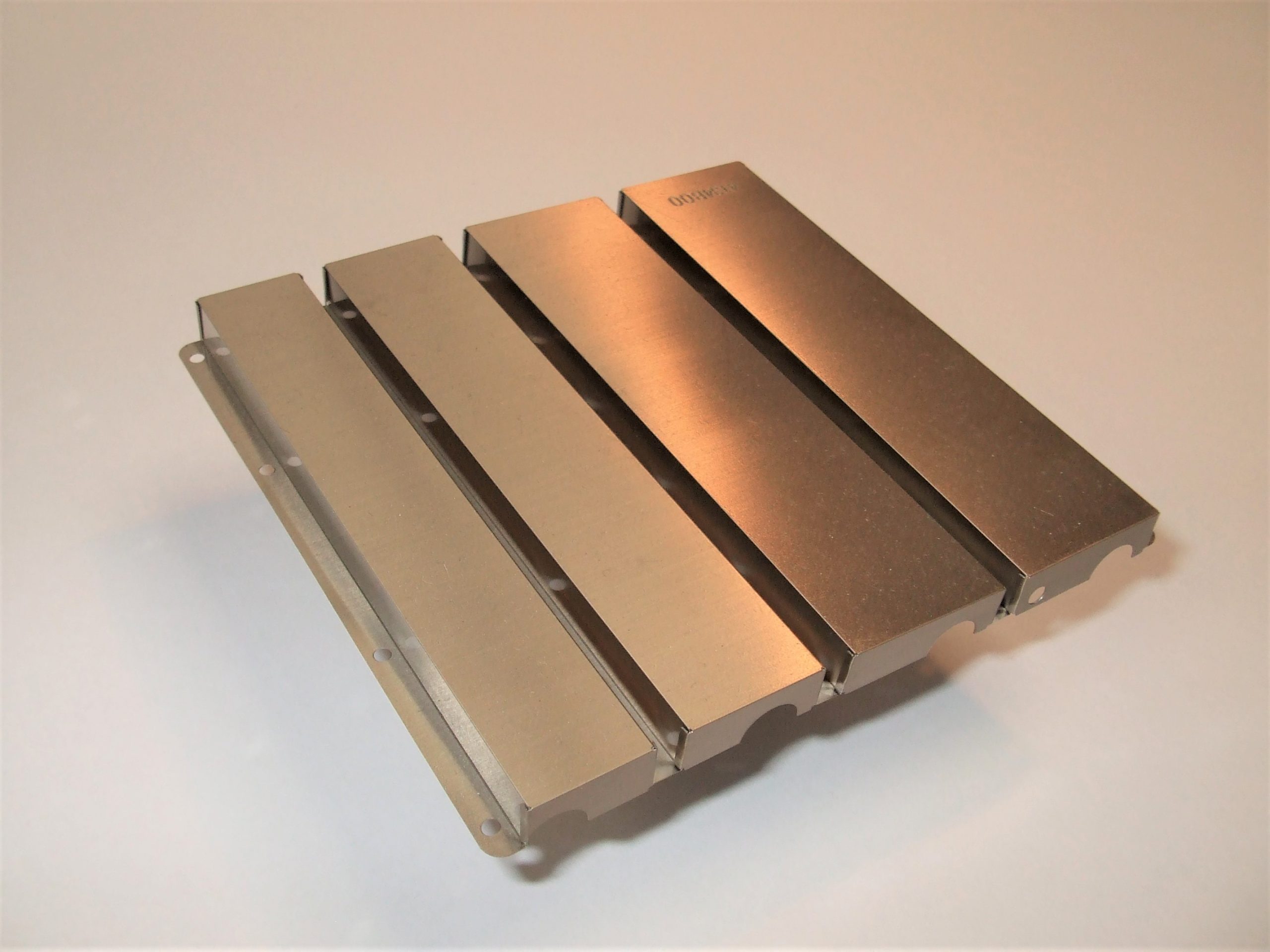

Chemical milling, or etching, is the best way to manufacture complex shaped parts, as the metal is not changed, there is no distortion from heat, and no oxide or cutting residues. Etching time is constant, no matter how complex the shape. Greater metal usage can be achieved by nesting components.

We can work with metal thickness down to 0.02 mm. Post etch processes can be carried out by using a half etch fold line, the position of bends and folds can be accurately controlled.

What is chemical milling?

The process work through applying a resist to both sides of a piece of flat sheet metal, and this resist can be screen printed. The resist covers the area that represents the part, and the rest is etched away. The resist is then removed to yield the part, and edges are smooth and not sharp. By using multiple resist-etch-strip sequences, some complex profiles can be made (like a stairway).

Looking to transform your engineering or electronic design, prototype or idea into reality?

Get in touch with Photoetch now.

Contact Us